FEA Analysis @ AnaMac

Finite Element Analysis Services We Offer

At AnaMac, our mechanical engineers, quality analysts, and FEA specialists, as an extension to your in-house team, are equipped with latest technical know-how and tools to ensure your designs are flawless. We provide FEA services for automotive sheet metal products, turbo machinery, industrial equipment, aerospace components, process equipment, structural building products, and a lot more. We offer an exhaustive list of FEA services that take care of all modeling requirements of your unique design concepts to final fabrication. Our major FEA services include -

-

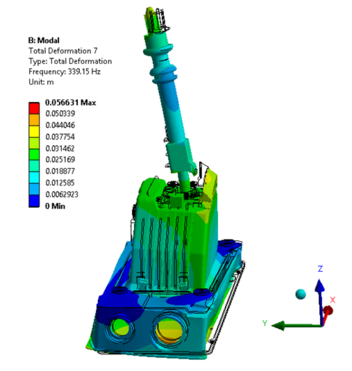

Static & Dynamic Analysis

AnaMac provides both static and dynamic analysis to provide accuracy and avoid machine faults. We have the required skills and expertise to provide the required services within a short time

-

Structural Analysis

Structural analysis is extremely beneficial in manufacturing where the cost, material, strength, weight, etc. have to be optimized. We provide finite element computer simulation to conduct structural engineering analysis for products and processes

-

Thermal Analysis (Steady State and Transient)

We use thermal analysis to ascertain temperature distribution in a component or assembly is done properly to ensure that it sustains when subjected to both internal and external sources of heat

-

Stress, Fracture Analysis, and Fatigue Analysis

We use this analysis to predict fatigue as well as fracture growth simulation to determine the durability of the components when subjected to complex loading situations like static, dynamic, and thermal

-

Composite Analysis

Reliability of the material used is of utmost importance for any manufacturing company. AnaMac conducts composite analysis to optimize designs and ensure the reliability of materials in the long-term

-

Explicit Dynamics Analysis

We employ explicit dynamics analysis to solve problems related to nonlinear problems like eroding contact, material failure, and large stain. We have the required skills and bandwidth to cater to all the challenges you are facing.